Recent Blog

Everything You Need to Know about GDI Injector

I. Types of Fuel Injection Systems

Every vehicle can be equipped with suitable fuel injection systems. There are the following types of injectors on the market:

a) Throttle body injectors

These injectors are located in the throttle body and are commonly used in older engines. Throttle body injectors spray fuel into the incoming air stream, which is then distributed to the engine cylinders.

b) Multiport injectors

Multiport injectors are used in most modern engines. They are located in the intake manifold and spray fuel directly into each cylinder. Multiport injectors can provide more precise fuel delivery and better engine performance than throttle body injectors.

c) Direct injectors

Direct injection injectors are used in modern engines with gasoline direct injection (GDI) technology. These injectors spray fuel directly into the combustion chamber, rather than into the intake manifold. DI injectors can provide better fuel efficiency and power than multiport injectors, but they can also be more prone to carbon buildup and require specialized cleaning.

d) Sequential fuel injectors

Sequential fuel injectors are a type of multiport injector that can deliver fuel to each cylinder in a specific order, based on the engine’s firing order. This can provide more precise fuel delivery and better engine performance.

e) Side feed injectors

Side feed injectors are a type of multiport injector that is installed on the side of the intake manifold. They can provide more efficient fuel delivery than top-feed injectors but can be more difficult to access for maintenance or replacement.

Overall, the type of fuel injector used in an engine can depend on factors such as the engine’s age, design, and fuel delivery technology.

II. The Benefits of GDI Injectors

There are several benefits of Gasoline Direct Injection (GDI) injectors, including:

a) Improved fuel efficiency

GDI injectors can provide better fuel efficiency than traditional port fuel injection systems because they deliver fuel directly into the combustion chamber, allowing for more precise control of the fuel-air mixture.

b) Increased power output

GDI injectors can also increase the engine’s power output by providing a more efficient combustion process. By delivering fuel directly into the combustion chamber, GDI injectors can provide a more complete burn of the fuel, resulting in more power and torque.

c) Reduced emissions

GDI injectors can help reduce emissions by providing a more precise fuel-air mixture, resulting in more complete combustion and lower emissions of harmful pollutants such as carbon monoxide and nitrogen oxides.

d) Improved cold-start performance

GDI injectors can also improve the engine’s cold-start performance by providing a more precise fuel-air mixture that is easier to ignite in cold temperatures.

e) Longer engine life

GDI injectors can help extend the life of the engine by reducing the build-up of carbon deposits on the intake valves and other engine components. By delivering fuel directly into the combustion chamber, GDI injectors can prevent the build-up of carbon deposits that can cause engine damage over time.

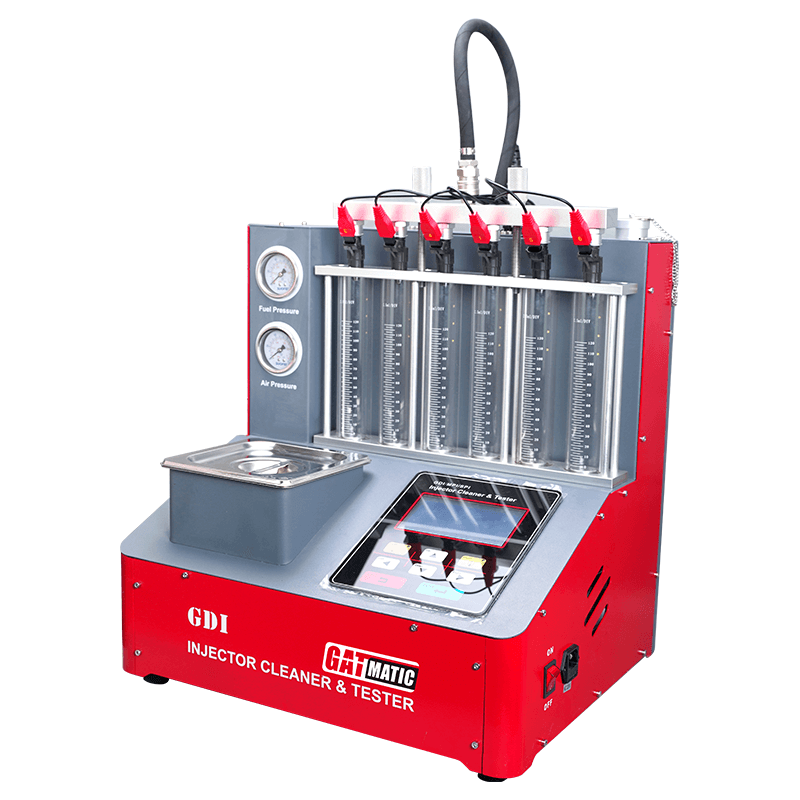

III. Best Choice for GDI Injector Cleaning Machine

GATmatic is a leading manufacturer and supplier of high-quality GDI injector cleaning machines in the automotive industry. With a focus on innovation and reliability, GATmatic is committed to offering customers high-quality products with effectiveness and efficiency.

GI-600DA is an ultrasonic automotive injector cleaner & tester from GATmatic. We upgrade the shell designed to sheet metal on this latest generation for more durable and reliable usage. Combining ultrasonic cleaning technology with microprocessor hydraulic control cleaning detection technology, GI-600DA can clean and inspect the car fuel injectors and fuel supply systems. And it is equipped with a storage cabinet that can store cleaning fluid, maintenance tools, etc.

IV. How Often Should You Do a GDI Cleaning

The answer to this question can vary depending on the specific vehicle and driving habits. Generally, it’s recommended to use a GDI injector cleaning machine every 30,000 to 50,000 miles, or every two to three years. However, if you frequently drive in stop-and-go traffic, on dusty roads, or in other conditions that can cause carbon build-up, you may want to use the machine more frequently.

It’s also important to note that using high-quality fuel and regularly changing your engine’s air filter can help reduce carbon build-up and extend the time between GDI injector cleanings. Ultimately, it’s best to consult your vehicle’s owner’s manual or a trusted mechanic for guidance on how often to use a GDI injector cleaning machine to maintain your engine’s performance.

V. FAQs

Q1: Why do GDI injectors need to be cleaned?

A1: Over time, carbon deposits and other contaminants can build up on GDI injectors, leading to reduced fuel efficiency, engine performance, and increased emissions. Cleaning the injectors helps to restore them to their optimal performance.

Q2: Can a GDI injector cleaning machine damage the injectors?

A2: When used correctly and with the appropriate chemicals, a GDI injector cleaning machine should not damage the injectors. However, if used improperly or with the wrong chemicals, it can potentially cause damage.

Q3: Can a GDI injector cleaning machine be used on diesel engines?

A3: No, GDI injector cleaning machines are specifically designed for gasoline direct injection engines and should not be used on diesel engines.

Q4: How long does the cleaning process take?

A4: The cleaning process can take anywhere from 30 minutes to an hour, depending on the machine and the condition of the injectors.

Q5: Is it necessary to remove the injectors from the engine to clean them?

A5: No, most GDI injector cleaning machines are designed to clean the injectors while they are still installed in the engine.

Describe Your Needs In Detail!

We will carefully evaluate your needs and give professional solutions.