Recent Blog

-

CCD Alignment Systems VS. 3D Alignment Systems

2025-04-08 -

What are the main differences between 2D and 3D wheel alignment systems

2025-03-26 -

Is Touchless Wheel Alignment Right for You? Factors to Consider

2025-03-19 -

The Future of Automotive Service: Exploring Touchless Wheel Alignment Technology

2025-03-13

What are the key benefits of using a 3D Wheel Aligner?

In the realm of vehicle maintenance, ensuring proper wheel alignment is paramount for optimal performance and safety. One technology that has revolutionized this aspect of automotive care is the 3D Wheel Aligner. Unlike traditional methods, which often rely on manual measurements and guesswork, a 3D Wheel Aligner offers unparalleled accuracy and efficiency in assessing and adjusting wheel alignment parameters. This essay explores the key benefits of adopting this advanced technology in automotive workshops and service centers.

I. Improved Accuracy and Precision

At the heart of the 3D Wheel Aligner lies its ability to provide three-dimensional measurements of wheel alignment parameters. This technology offers enhanced precision compared to conventional two-dimensional systems, allowing for the detection and correction of even minor misalignments that could compromise vehicle handling and tire wear. By leveraging advanced sensors and software algorithms, a 3D Wheel Aligner ensures that alignment adjustments are carried out with the utmost accuracy, contributing to improved driving dynamics and safety on the road.

II. Time Efficiency

Time is of the essence in any automotive service operation, and here too, the 3D Wheel Aligner shines. With its quick setup and measurement process, technicians can perform wheel alignments swiftly, minimizing labor time and reducing vehicle downtime. Gone are the days of labor-intensive manual measurements and trial-and-error adjustments. The streamlined workflow enabled by a 3D Wheel Aligner not only boosts productivity in the workshop but also enhances customer satisfaction by getting vehicles back on the road faster.

III. Comprehensive Data Analysis

Beyond mere alignment adjustments, a 3D Wheel Aligner offers comprehensive data analysis capabilities. Technicians can access detailed reports containing precise measurements of wheel angles, including camber, caster, and toe, among others. This wealth of diagnostic information enables them to identify potential issues with suspension components or steering geometry that may affect alignment or vehicle performance. By addressing these underlying issues proactively, technicians can prevent premature tire wear and mitigate the risk of more costly repairs down the line.

IV. Enhanced Customer Satisfaction

Ultimately, the primary goal of any automotive service provider is to ensure customer satisfaction. By investing in a 3D Wheel Aligner, workshops can deliver tangible benefits to their customers. Improved vehicle handling and performance translate into a more enjoyable driving experience for vehicle owners. Moreover, by extending the lifespan of tires and reducing fuel consumption through optimized alignment, technicians demonstrate a commitment to cost-effectiveness and sustainability. The professionalism and quality of service associated with the use of advanced alignment technology further enhance the reputation of the workshop in the eyes of customers.

V. Cost Savings

In addition to enhancing customer satisfaction, a 3D Wheel Aligner offers tangible cost savings for both vehicle owners and service providers alike. By preventing premature tire wear and reducing fuel consumption, optimized wheel alignment translates into fewer expenses associated with tire replacements and increased fuel efficiency. Moreover, by detecting and addressing suspension issues early on, technicians can minimize the risk of more extensive and costly repairs in the future, saving both time and money for vehicle owners.

VI. Compatibility and Adaptability

One of the key advantages of a 3D Wheel Aligner is its compatibility with a wide range of vehicles, from compact cars to heavy-duty trucks. Moreover, it can adapt to various wheel sizes and configurations, ensuring versatility in the workshop. Whether dealing with standard passenger vehicles or specialized commercial fleets, technicians can rely on a 3D Wheel Aligner to deliver accurate and reliable results across the board. Furthermore, integration with other diagnostic and repair systems allows for seamless workflow integration, further enhancing efficiency and productivity in the workshop.

Conclusion

In conclusion, the adoption of a 3D Wheel Aligner represents a significant leap forward in the field of vehicle maintenance and repair. By offering improved accuracy and precision, time efficiency, comprehensive data analysis, enhanced customer satisfaction, cost savings, and compatibility, this advanced technology empowers automotive workshops to deliver superior service and performance to their customers. As the automotive industry continues to evolve, the use of 3D Wheel Aligners will undoubtedly remain a cornerstone of modern vehicle maintenance practices, ensuring optimal performance and safety on the road for years to come.

FAQs

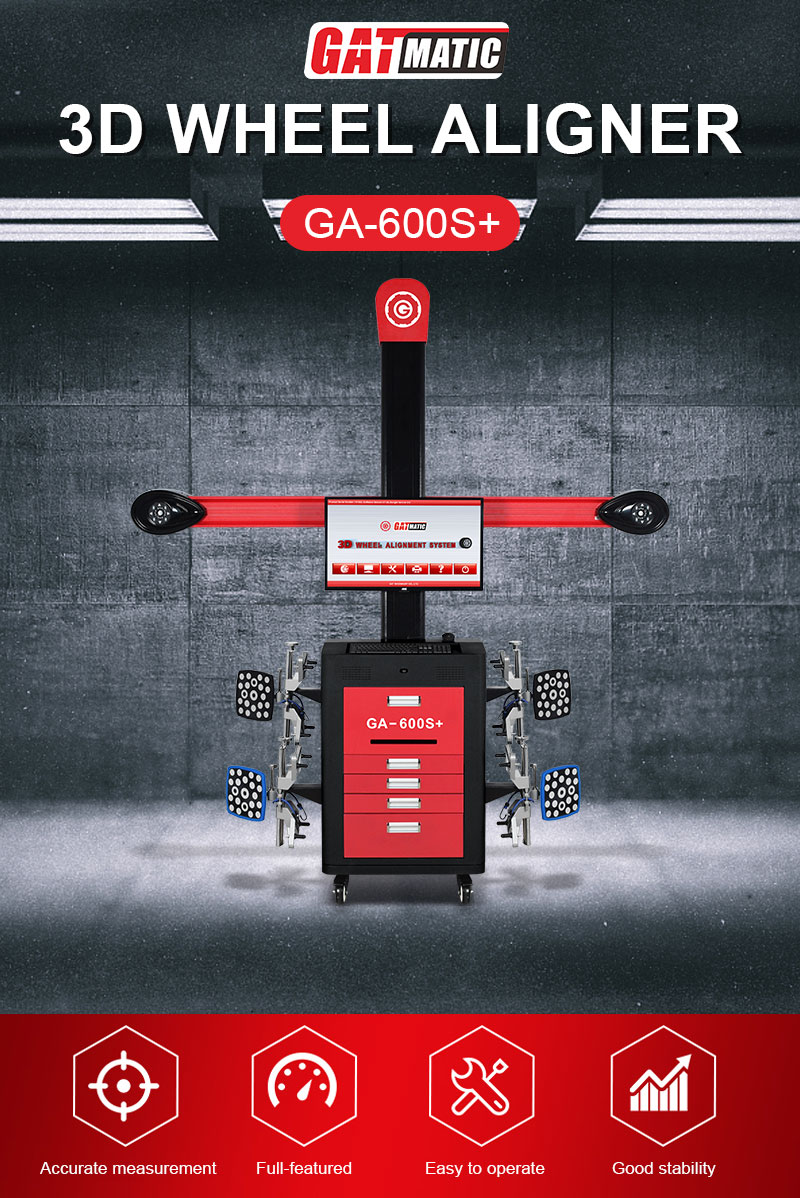

1. What is a 3D Wheel Aligner?

A 3D Wheel Aligner is an advanced diagnostic tool used in automotive workshops to assess and adjust the alignment of a vehicle’s wheels accurately. Unlike traditional aligners, it provides three-dimensional measurements of wheel angles for enhanced precision.

2. How does a 3D Wheel Aligner work?

A 3D Wheel Aligner employs advanced sensors and cameras to capture precise measurements of wheel angles such as camber, caster, and toe. The data collected is then analyzed by specialized software, which generates detailed reports and recommendations for alignment adjustments.

3. What are the benefits of using a 3D Wheel Aligner?

Some key benefits include improved accuracy and precision, time efficiency, comprehensive data analysis, enhanced customer satisfaction, cost savings, and compatibility with various vehicle types and configurations.

4. How often should wheel alignment be performed using a 3D Wheel Aligner?

It is recommended to have the wheel alignment checked whenever there are signs of steering or handling issues, uneven tire wear, or after hitting a pothole or curb. Additionally, regular maintenance intervals, such as during tire rotations or suspension inspections, provide opportunities to check and adjust alignment as needed.

5. Can a 3D Wheel Aligner detect suspension problems?

Yes, one of the advantages of a 3D Wheel Aligner is its ability to detect suspension issues that may affect wheel alignment or vehicle performance. By analyzing the data collected during alignment measurements, technicians can identify abnormalities in suspension geometry and recommend appropriate repairs or adjustments.

6. How long does a wheel alignment session take with a 3D Wheel Aligner?

The duration of a wheel alignment session using a 3D Wheel Aligner can vary depending on factors such as the complexity of the alignment adjustments needed, the condition of the vehicle, and the technician’s proficiency. However, the streamlined workflow enabled by advanced technology typically results in shorter turnaround times compared to traditional alignment methods.

Describe Your Needs In Detail!

We will carefully evaluate your needs and give professional solutions.