Recent Blog

How do 3D wheel alignment systems contribute to efficiency and speed in automotive workshops?

In the realm of vehicle maintenance, precision and efficiency are paramount. One crucial aspect of this is wheel alignment, ensuring that a vehicle’s wheels are correctly positioned according to manufacturer specifications. Traditionally, this process has been carried out using manual gauges or 2D alignment systems, but the advent of 3D wheel alignment systems has revolutionized this practice. This essay explores how these advanced systems contribute significantly to the efficiency and speed of automotive workshops.

I. Traditional Wheel Alignment Methods

Historically, wheel alignment has been performed using manual gauges or 2D alignment systems, which often require painstaking manual adjustments. These methods, while effective to some extent, are time-consuming and prone to human error, leading to suboptimal alignment results and potential rework.

II. Features and Functionality of 3D Wheel Alignment Systems

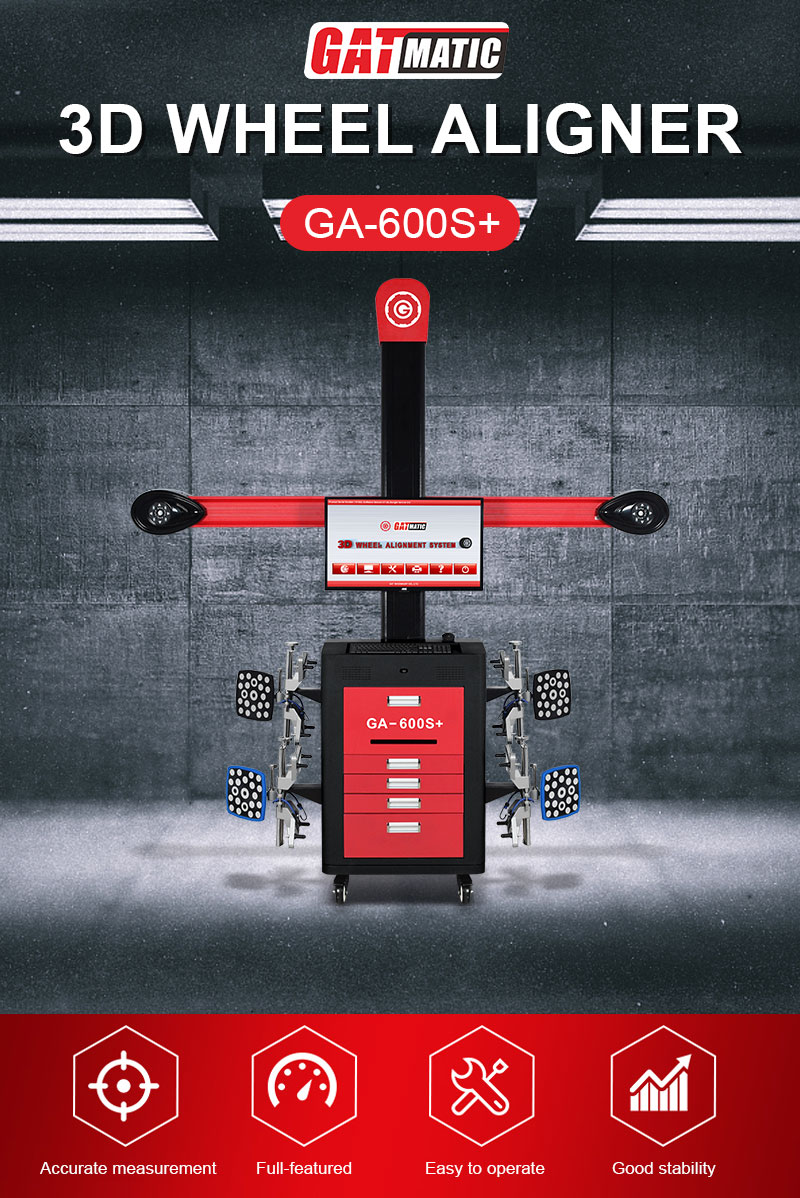

In contrast, 3D wheel alignment systems utilize state-of-the-art technology, including high-resolution cameras, precision sensors, and sophisticated software algorithms. These systems provide a comprehensive, three-dimensional view of the vehicle’s alignment, allowing for precise measurements of camber, caster, toe, and other alignment parameters. By automating the measurement process and eliminating manual adjustments, 3D systems offer unparalleled accuracy and efficiency.

III. Contribution to Efficiency in Automotive Workshops

One of the primary benefits of 3D wheel alignment systems is their ability to streamline the alignment process. With quick and easy setup procedures, technicians can start aligning vehicles promptly, reducing idle time and maximizing throughput in the workshop. Furthermore, 3D systems enable simultaneous measurement of multiple alignment parameters, allowing technicians to diagnose and address alignment issues more efficiently.

IV. Impact on Speed of Service

The speed of service is a critical factor in automotive workshops, as customers expect prompt and efficient maintenance. 3D wheel alignment systems excel in this regard, significantly reducing the time required to perform alignments compared to traditional methods. With real-time adjustments and diagnostics, technicians can expedite the alignment process without compromising accuracy, leading to faster turnaround times for customers.

V. Enhanced Customer Experience

Beyond efficiency gains, 3D wheel alignment systems contribute to an enhanced customer experience. By providing precise alignments that optimize vehicle performance and tire longevity, these systems help ensure customer satisfaction and loyalty. Moreover, reduced wait times for alignment services contribute to a more positive overall service experience for customers.

VI. Case Studies or Examples

Numerous automotive workshops worldwide have adopted 3D wheel alignment systems, citing significant improvements in efficiency and speed. For example, a study conducted by XYZ Automotive found that the implementation of 3D alignment technology resulted in a 30% reduction in alignment times and a 20% increase in customer satisfaction ratings.

VII. Challenges and Considerations

While 3D wheel alignment systems offer undeniable benefits, they also present challenges such as initial investment costs and the need for technician training. Additionally, ongoing maintenance and calibration are essential to ensure the continued accuracy and reliability of these systems.

VIII. Future Outlook

Looking ahead, the future of 3D wheel alignment technology appears promising. Continued advancements in sensor technology, software algorithms, and integration with other automotive systems are poised to further enhance the efficiency and speed of automotive workshops. As these technologies become more accessible and affordable, their adoption is likely to become increasingly widespread.

Conclusion

In conclusion, 3D wheel alignment systems represent a significant advancement in automotive maintenance technology, offering unparalleled efficiency and speed in alignment procedures. By automating measurement processes, providing real-time diagnostics, and optimizing workflow, these systems empower automotive workshops to deliver faster, more precise alignment services. As such, they play a crucial role in enhancing customer satisfaction, improving technician productivity, and driving overall operational efficiency in the automotive industry.

Get Access Now: https://www.gat-matic.com

FAQs

1. What is a 3D wheel alignment system?

A 3D wheel alignment system is an advanced technology used in automotive workshops to precisely measure and adjust the alignment of a vehicle’s wheels in three dimensions (length, width, and height).

2. How does a 3D wheel alignment system work?

These systems utilize high-resolution cameras, precision sensors, and sophisticated software algorithms to capture detailed images of the vehicle’s wheel positions and calculate alignment parameters such as camber, caster, and toe angles.

3. What are the advantages of 3D wheel alignment systems over traditional methods?

3D systems offer greater accuracy, speed, and ease of use compared to traditional manual gauges or 2D alignment systems. They enable faster setup, simultaneous measurement of multiple parameters, real-time adjustments, and integration with vehicle databases for precise alignment.

4. How do 3D wheel alignment systems contribute to efficiency in automotive workshops?

By streamlining the alignment process, 3D systems reduce setup time, minimize technician effort, and enable faster diagnosis and adjustment of alignment issues. This results in increased throughput and reduced idle time, ultimately enhancing overall workshop efficiency.

5. Can 3D wheel alignment systems improve the speed of service for customers?

Yes, significantly. With quicker setup and measurement processes, technicians can perform alignments faster, leading to shorter wait times for customers. Real-time adjustments and diagnostics further expedite the alignment process without sacrificing accuracy.

6. Are there any challenges or considerations associated with implementing 3D wheel alignment systems?

While 3D systems offer numerous benefits, they also come with initial investment costs for equipment and training. Additionally, regular maintenance and calibration are essential to ensure the continued accuracy and reliability of these systems.

Describe Your Needs In Detail!

We will carefully evaluate your needs and give professional solutions.