What are the key differences between CCD and 3D wheel aligners

Introduction

Wheel alignment is a crucial aspect of vehicle maintenance that ensures optimal performance, safety, and tire longevity. Proper alignment prevents uneven tire wear and enhances the handling and stability of the vehicle. In the realm of automotive service, two advanced technologies have emerged to facilitate accurate wheel alignment: CCD (Charged Coupled Device) and 3D wheel aligners. While both systems serve the same fundamental purpose, they employ different technologies and methodologies, leading to distinct advantages and disadvantages.

1. Technology Used

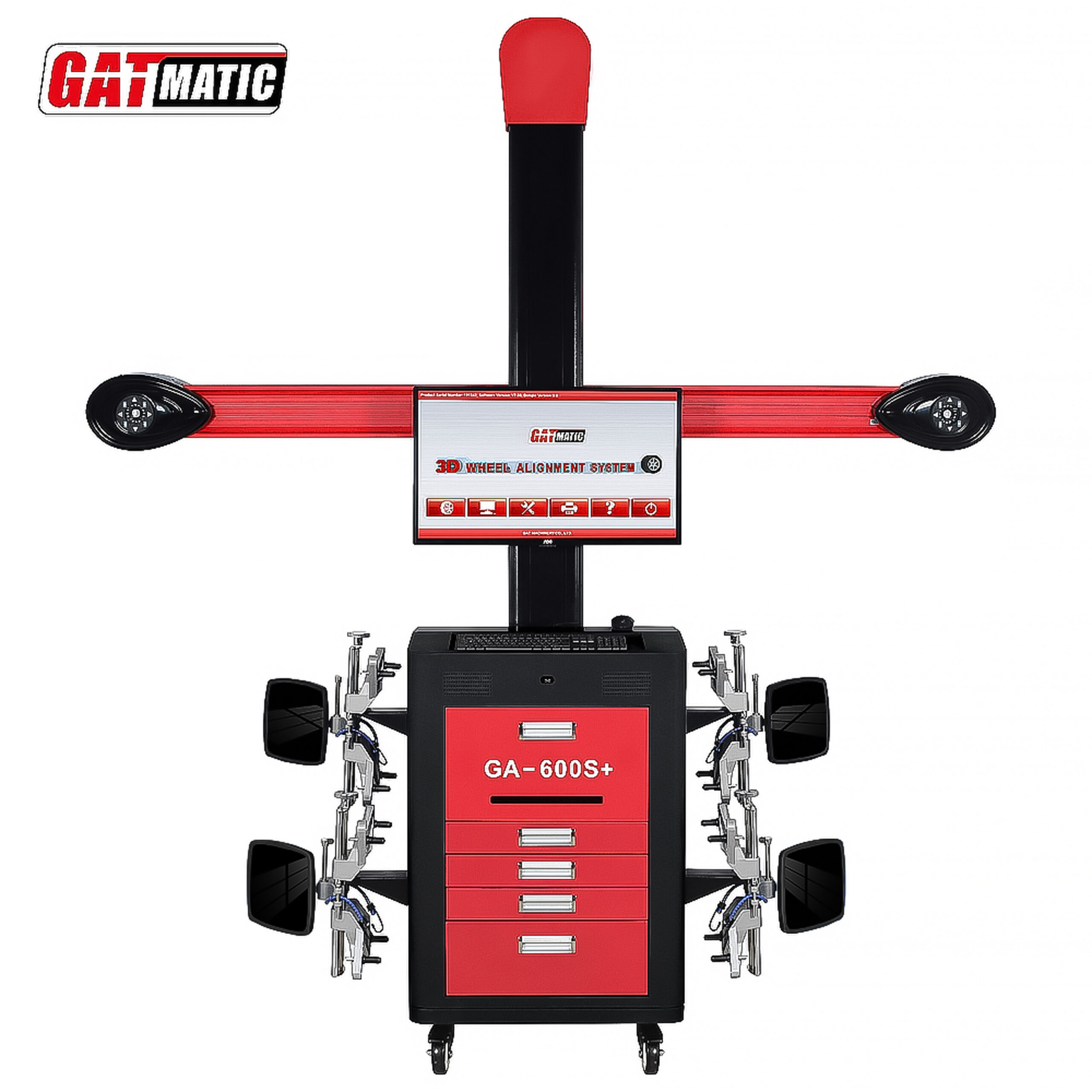

CCD Wheel Aligners utilize camera technology to measure wheel angles. This system typically employs four measuring heads that are clamped onto each wheel, capturing real-time data as the vehicle is positioned on the alignment rack. The CCD technology translates the captured images into precise measurements of camber, caster, and toe angles, allowing technicians to make necessary adjustments.In contrast, 3D Wheel Aligners leverage high-definition cameras, lasers, and sensors to create a comprehensive three-dimensional model of the vehicle’s wheel alignment. This technology measures angles across three dimensions (X, Y, Z axes), providing a more detailed analysis than traditional methods. The ability to visualize alignment in three dimensions allows for greater accuracy in diagnosing alignment issues.

2. Accuracy and Precision

When it comes to accuracy, CCD Aligners are known for their reliability in aligning wheels to manufacturer specifications. They provide consistent results with less manual intervention compared to traditional systems. However, while CCD technology is effective for most vehicles, it may not capture minute deviations as effectively as newer systems.On the other hand, 3D Aligners offer superior precision due to their advanced technology. They can detect even the slightest misalignments, making them ideal for high-performance vehicles that require meticulous alignment. The enhanced accuracy of 3D systems can lead to improved handling characteristics and extended tire life.

3. Speed and Efficiency

In terms of speed and efficiency, CCD Systems generally allow for faster setup times, often operational in under five minutes. Their user-friendly design makes them suitable for high-volume service environments where quick turnarounds are essential.Conversely, 3D Systems, while still relatively fast, may require more time for setup due to their complex calibration processes. Technicians must ensure that all sensors and cameras are correctly aligned before beginning the measurement process, which can extend the time needed for each alignment job.

4. Flexibility and Portability

CCD Aligners offer significant flexibility and portability; they can be used on various lifts and are not locked to a specific alignment bay. This mobility allows service providers to transport them between different locations easily, making them ideal for businesses that operate in multiple settings or require on-site services.In contrast, 3D Aligners are often fixed in place due to the need for specialized equipment and calibration setups. This limitation reduces their flexibility in terms of location but allows for a more stable measurement environment once set up.

5. Cost Considerations

When evaluating cost considerations, CCD Systems tend to be more cost-effective regarding initial investment and ongoing maintenance. They typically have fewer perishable parts that require replacement over time, leading to lower long-term operational costs.In contrast, 3D Systems usually involve a higher initial investment due to their advanced features and technology. However, many businesses find that the enhanced capabilities justify this expense, particularly if they cater to high-performance vehicles or require detailed diagnostic reporting.

6. Diagnostic and Reporting Capabilities

In terms of diagnostic capabilities, CCD Aligners provide basic diagnostics with real-time measurements against manufacturer specifications. They are effective for standard alignment tasks but may lack advanced reporting features.On the other hand, 3D Aligners boast enhanced diagnostic features that include detailed reporting capabilities. These systems can generate visual before-and-after comparisons of wheel alignment adjustments, providing valuable insights for technicians and customers alike.

Conclusion

In summary, both CCD and 3D wheel aligners play vital roles in modern automotive service by ensuring accurate wheel alignment. The key differences between these two systems lie in their technology, accuracy, speed, flexibility, cost considerations, and diagnostic capabilities. When choosing between a CCD or 3D wheel aligner, businesses should consider their specific needs based on the types of vehicles serviced and customer demands. Ultimately, investing in the right alignment technology can enhance service quality while improving customer satisfaction and vehicle performance.

FAQs

1. What is the main difference between CCD and 3D wheel aligners?

CCD (Charged Coupled Device) wheel aligners use cameras and sensors to capture real-time images of wheel positions, while 3D wheel aligners utilize advanced cameras and lasers to create a three-dimensional model of the vehicle’s alignment parameters. This difference in technology leads to variations in accuracy, speed, and flexibility.

2. Which system is more accurate, CCD or 3D?

Both CCD and 3D alignment systems are highly accurate, but some tests have shown that CCD systems can be slightly more precise because their measuring sensors attach directly to the wheel rather than relying on images of targets mounted on the wheels

3. How quickly can each system perform an alignment?

CCD systems can typically provide accurate vehicle measurements in under five minutes, making them efficient for high-volume service environments. Conversely, while 3D systems are also fast, they may require additional time for setup due to their complex calibration processes.

4. Are CCD aligners more flexible than 3D aligners?

Yes, CCD aligners are more flexible as they can be used in various bays with a four-post lift and are not locked to a specific alignment rack. This allows for greater adaptability in service locations compared to 3D systems, which often require specialized equipment.

5. What types of vehicles can each system align?

CCD systems can align a wider variety of vehicles, including larger and specialty vehicles that may not fit on standard 3D alignment lifts. In contrast, 3D systems may be limited in their capacity for larger vehicles.

6. What are the cost implications of using CCD vs. 3D aligners?

CCD systems generally have a lower initial investment and ongoing maintenance costs compared to 3D systems. They often feature fewer proprietary parts that need replacement, leading to cost savings over time.

7. Do both systems provide diagnostic capabilities?

Yes, both CCD and 3D systems offer diagnostic capabilities; however, 3D systems typically provide enhanced reporting features, including visual before-and-after comparisons of wheel alignment adjustments. This can improve communication between mechanics and vehicle owners.

Describe Your Needs In Detail!

We will carefully evaluate your needs and give professional solutions.