Recent Blog

-

CCD Alignment Systems VS. 3D Alignment Systems

2025-04-08 -

What are the main differences between 2D and 3D wheel alignment systems

2025-03-26 -

Is Touchless Wheel Alignment Right for You? Factors to Consider

2025-03-19 -

The Future of Automotive Service: Exploring Touchless Wheel Alignment Technology

2025-03-13

CCD Alignment Systems VS. 3D Alignment Systems

With the development of technology, the transition from CCD to 3D and then to 5D wheel alignment systems involves significant advancements in technology, accuracy, and functionality.

I. Introduction

When we mention Wheel Aligners, there will be CCD Wheel Aligner and 3D Wheel Aligner. While CCD Wheel Aligner and 3D Wheel Aligner help workshop engineers accurately perform professional and very easy alignment work. They differ in technology when comparing CCD Alignment Systems and 3D Alignment Systems. There are several major differences to determine which is more suitable for specific needs.

II. Definition

- CCD

A charge-coupled device (CCD) is a light-sensitive integrated circuit that captures images by converting photons to electrons. A CCD sensor breaks the image elements into pixels. Each pixel is converted into an electrical charge whose intensity is related to the intensity of light captured by that pixel.1

- 3D

These systems utilize advanced cameras and sensors to create a three-dimensional model of the vehicle’s alignment parameters. This technology provides a comprehensive view of camber, caster, and toe angles, allowing mechanics to identify even the slightest misalignments, achieved with speed and efficiency. Additionally, the visual representation of the alignment data simplifies communication between mechanics and vehicle owners, enhancing transparency and trust.2

III. Difference

- Accuracy and Technology

CCD Systems: CCD systems usually use 20-degree advanced camera technology to capture real-time images of wheel positions, providing high accuracy by attaching measuring sensors(such as 8 sensors)3 directly to the wheels. They are often considered slightly more accurate than 3D systems.

3D Systems: Use 3D positioning technology4 and sensors to create a three-dimensional model of alignment parameters, offering comprehensive views of camber, caster, and toe angles. They are also highly accurate but may not surpass CCD systems in precision. While it can perform dynamic constitute coordinate and will not be affected by the inclination of lift.

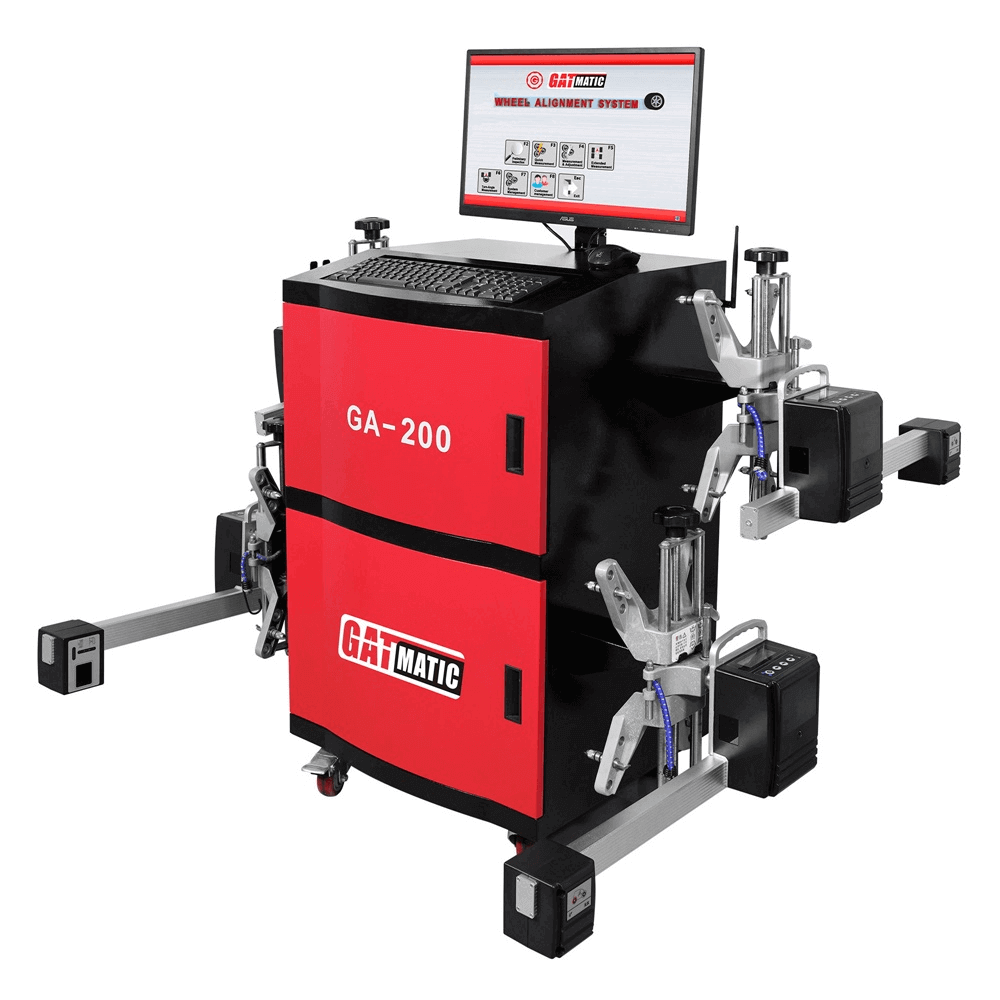

| CCD Wheel Aligner(GA-200) | 3D Wheel Aligner(GA-600s) | |

| Toe-in | ±2′ | ±2′ |

| Camber | ±2′ | ±2′ |

| Caster | ±6′ | ±4′ |

| SAI/KPI | ±6′ | ±6′ |

| Setback | ±2′ | ±2′ |

| Thrust Angle | ±2′ | ±2′ |

Data from GATmatic products: GA-200 CCD Wheel Aligner & GA-600S 3D Wheel Aligner.

- Flexibility and Space Requirements

CCD Systems: Portable and can be used on any lift, including two-post lifts. They are easy to move around, making them ideal for garages with limited space or those needing flexibility in their operations. Through remote control pressing the key on the sensor head, may complete all wheel alignment operations, such as our GA-200 CCD Wheel Aligner.

3D Systems: Typically require a fixed position in front of a lift, which can limit their use to specific bays and may necessitate more space. The convenience and easy operation can help small garage save space, such as our GA-600S 3D Wheel Aligner.

- Cost and Investment

CCD Systems: Often be more cost-effective and provide super stable, accurate features.

3D Systems: With slightly higher price than CCD and usually can be movable during the test with more convenient and easier operation.

Conclusion

In Summary, both CCD (Charge-Coupled Device) and 3D alignment systems signify substantial progressions within the realm of wheel alignment technology. Compared to conventional techniques, they bring about remarkable enhancements in terms of both precision and operational efficiency. When it comes to deciding between these two advanced systems, automotive service providers typically need to consider their unique requirements and key priorities, as these factors will ultimately guide the most suitable choice for their specific business operations.

FAQs

1. Can CCD Wheel Aligner be used with all types of vehicles?

CCD wheel alignment systems can be used with a wide variety of vehicles, including cars and light trucks. They are versatile and can handle different types of suspensions, such as independent four-wheel suspensions and light trucks

2. Are there any specific brands of CCD alignment systems that are highly recommended ?

You can have a look at GATmatic Brand: GA-200H designed for Heavy-Duty Truck.

3. Can 3D Wheel Aligner be suitable for all types of lifts?

It can perform wheel aligners on 2 post lifts and small scissor lifts, which is unique in the industry with patents.

4. How does the setup time for CCD systems compare to 3D systems?

The setup time of CCD alignment systems is generally on par with, if not quicker than, that of 3D alignment systems. Seasoned technicians can set up and make both systems operational in under five minutes. Notably, CCD systems are renowned for their straightforward setup process and high flexibility. They can be deployed on any lift and are not restricted to a particular bay or alignment rack.

5. How does the accuracy of CCD alignment systems compare to 3D alignment systems?

The accuracy of CCD alignment systems and 3D alignment systems depends on various factors and specific application requirements. While CCD alignment systems are suitable for many 2D alignment tasks, 3D alignment systems offer greater accuracy and flexibility in 3D applications.

Describe Your Needs In Detail!

We will carefully evaluate your needs and give professional solutions.