Gat-matic Auto Tracking 3D Movable Wheel Alignment Machine How to use

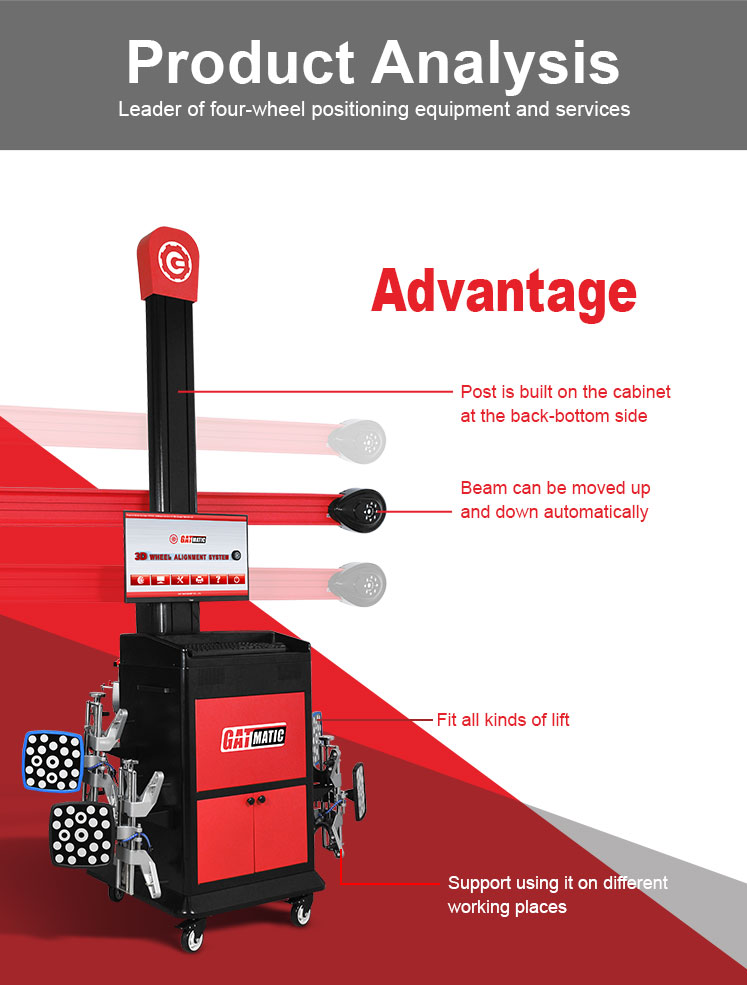

In the intricate realm of automotive maintenance, few aspects are as crucial as proper wheel alignment. The advent of technology has introduced advanced solutions to this age-old concern, and at the forefront stands the Gat-matic Auto Tracking 3D Movable Wheel Alignment Machine. With a relentless focus on precision and efficiency, this cutting-edge equipment redefines the art of wheel alignment. This essay will provide a comprehensive guide on how to proficiently operate the Gat-matic machine, ensuring optimal vehicle performance and safety.

I. Preparing for Wheel Alignment

Before embarking on the wheel alignment process, it is paramount to establish a solid foundation. Begin by ensuring that the machine is set up correctly and calibrated accurately. Placing the machine on a level surface is the first step, followed by meticulous calibration of the sensors as per the manufacturer’s instructions. A thorough inspection of the vehicle is essential, checking for any visible damage to tires, wheels, and suspension components. Additionally, verify that tire pressures are at recommended levels to prevent skewed alignment readings. Assemble all the necessary tools and documentation, including the user manual for the Gat-matic machine and the specific vehicle specifications.

II. Setting Up the Vehicle

Positioning the vehicle correctly is a crucial prerequisite for a successful alignment procedure. Drive the vehicle onto the alignment rack or lift, ensuring that it is centrally placed within the machine’s measurement area. Secure the vehicle in place by engaging the parking brake and utilizing wheel chocks to prevent any unintended movement.

III. Using the Gat-matic Auto Tracking 3D Movable Wheel Alignment Machine

- Power On and Vehicle Selection: Begin by powering on the Gat-matic machine and then proceed to input the relevant vehicle specifications, including its make, model, and year.

- Follow On-Screen Prompts: Depending on the machine’s user interface, follow the on-screen instructions to navigate through the alignment process.

- Capture Initial Measurements: Allow the machine’s sophisticated sensors to scan the current wheel alignment parameters of the vehicle, providing a baseline for adjustments.

- Make Necessary Adjustments: Carefully review the alignment data and identify any misalignments. With the guidance of the machine’s interface, make the required adjustments to the wheel angles.

- Re-Measure Alignment Angles: After making adjustments, conduct another scan of the vehicle to verify that the alignment angles now fall within the acceptable range.

- Fine-Tune as Necessary: If needed, continue fine-tuning the adjustments until all alignment angles meet the specified requirements, ensuring optimal precision.

IV. Finalizing the Process

Upon achieving the desired alignment, it’s time to finalize the process:

- Save Alignment Data: Store the final alignment measurements within the machine for documentation and future reference.

- Provide Alignment Report: Generate a comprehensive alignment report that outlines the initial measurements, adjustments made, and the final alignment angles achieved. This report serves as valuable evidence of the alignment procedure’s success.

- Offer Recommendations: To ensure the longevity of the alignment’s effectiveness, provide the customer with recommendations for ongoing vehicle maintenance that supports proper alignment.

V. Safety and Maintenance

Post-alignment responsibilities encompass safety and maintenance:

- Turn Off the Machine: After concluding the alignment process, remember to power off the Gat-matic machine.

- Clean and Maintain Sensors: Regularly clean and maintain the sensors and moving parts according to the manufacturer’s guidelines to guarantee accurate readings and prolonged machine lifespan.

- Prioritize Safety: Adhere to all safety procedures while operating the machine to prevent accidents and ensure a secure working environment.

Conclusion

In the modern age of automotive technology, the Gat-matic Auto Tracking 3D Movable Wheel Alignment Machine is a beacon of accuracy and efficiency in the field of wheel alignment. This guide has illuminated the step-by-step process to masterfully employ this advanced tool, underscoring the significance of proper wheel alignment for vehicle performance and safety. By adhering to the outlined procedures and heeding the manufacturer’s instructions, technicians and operators can confidently navigate the intricate domain of wheel alignment, ensuring vehicles roll smoothly and safely on the road ahead.

Describe Your Needs In Detail!

We will carefully evaluate your needs and give professional solutions.