How accurate are 3D wheel alignment systems compared to traditional methods?

I. Introduction

Wheel alignment is a critical aspect of vehicle maintenance that ensures optimal performance, safety, and tire longevity. As automotive technology advances, so do the methods used for wheel alignment. This essay explores the accuracy of 3D wheel alignment systems compared to traditional methods, providing insights into their respective strengths and limitations.

II. Traditional Wheel Alignment Methods

Traditional wheel alignment techniques have been the industry standard for decades. These methods typically involve mechanical tools such as gauges, strings, and plumb bobs. While these tools have served the automotive industry well, they come with inherent limitations. The accuracy of traditional methods largely depends on the technician’s skill and experience. Potential sources of error include parallax issues, worn equipment, and environmental factors like uneven surfaces.

III. 3D Wheel Alignment Systems

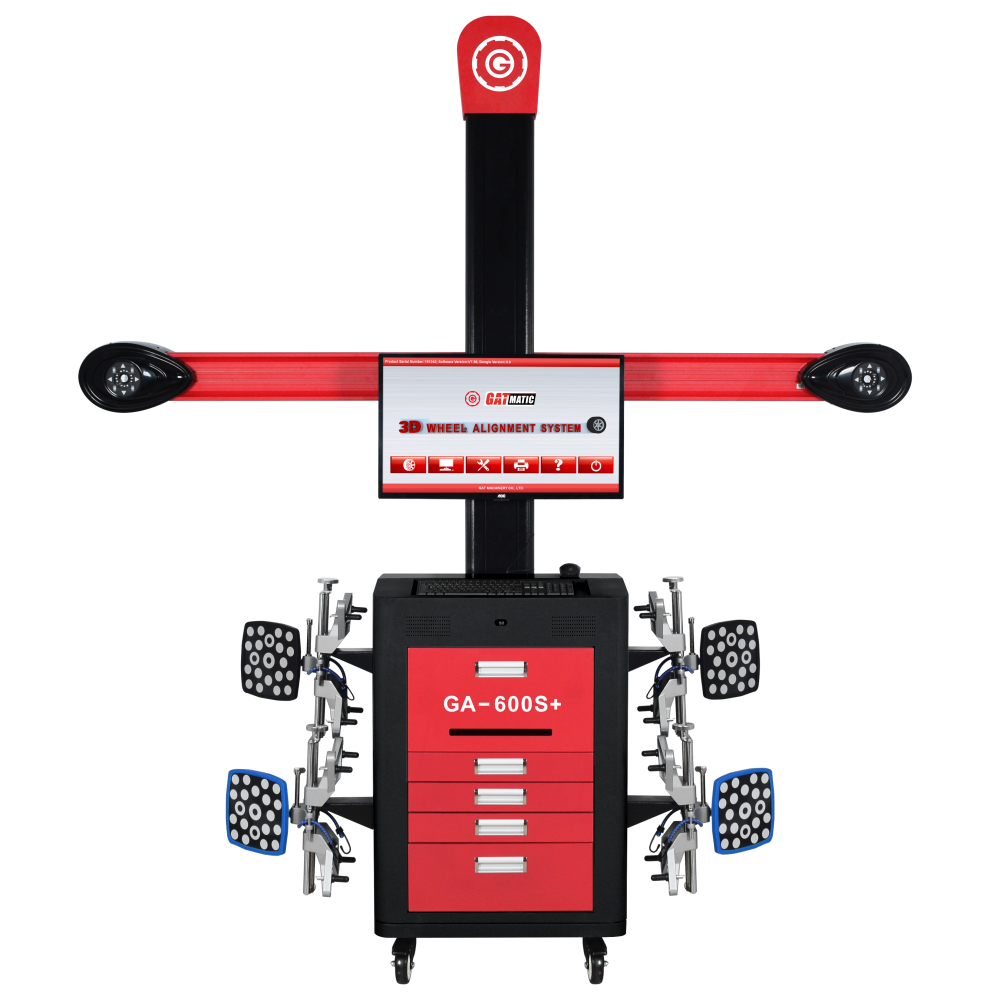

3D wheel alignment systems represent a significant technological leap. These systems use high-resolution cameras and reflective targets to create a three-dimensional model of the vehicle’s suspension. The primary advantages of 3D systems include faster setup times, real-time measurements, and the ability to compensate for vehicle weight. However, they may face challenges in extreme lighting conditions or with certain vehicle designs.

IV. Comparative Analysis

When comparing 3D systems to traditional methods, several factors come into play. 3D systems generally offer superior accuracy due to their ability to measure multiple angles simultaneously and eliminate human error. They are also significantly faster, reducing alignment times from hours to minutes. The learning curve for 3D systems can be steeper, but they often provide more consistent results across different operators.

V. Factors Affecting Accuracy

Regardless of the method used, several factors can impact alignment accuracy. Equipment calibration is crucial for both traditional and 3D systems. Operator skill and training play a more significant role in traditional methods, while 3D systems rely more on software algorithms. Environmental factors such as temperature and humidity can affect both methods, and the vehicle’s condition, including worn suspension components, can skew results.

VI. Case Studies and Research Findings

Numerous studies have compared 3D and traditional alignment methods. For instance, a study by the Society of Automotive Engineers found that 3D systems consistently produced more accurate results across a range of vehicle types. Many automotive manufacturers now recommend 3D alignment systems for their precision and ability to handle complex suspension geometries.

VII. Cost-Benefit Analysis

While 3D alignment systems require a higher initial investment, they often prove more cost-effective in the long run. The increased speed and accuracy lead to higher customer satisfaction and fewer comebacks. Additionally, the reduced physical strain on technicians can lead to lower injury rates and associated costs. However, ongoing calibration and software updates for 3D systems must be factored into the total cost of ownership.

VIII. Future Trends

The future of wheel alignment technology looks promising. Emerging technologies such as augmented reality interfaces and machine learning algorithms are poised to further improve the accuracy and ease of use of alignment systems. These advancements may blur the line between 3D and traditional methods, potentially leading to hybrid systems that combine the best of both worlds.

Conclusion

In conclusion, while both traditional and 3D wheel alignment methods have their place in the automotive industry, 3D systems generally offer superior accuracy, efficiency, and consistency. As technology continues to evolve, it’s likely that 3D systems will become the new standard in wheel alignment. However, automotive professionals should remain adaptable, as the field continues to advance rapidly. Ultimately, the choice between traditional and 3D methods should be based on factors such as the specific needs of the workshop, the types of vehicles serviced, and the long-term return on investment.

FAQs

1. What is the main difference between 3D wheel alignment systems and traditional methods?

3D wheel alignment systems use high-resolution cameras and reflective targets to create a three-dimensional model of the vehicle’s suspension, while traditional methods rely on mechanical tools such as gauges, strings, and plumb bobs.

2. Are 3D wheel alignment systems more accurate than traditional methods?

Generally, 3D systems offer superior accuracy due to their ability to measure multiple angles simultaneously and eliminate human error. However, the accuracy of both methods can be affected by various factors such as equipment calibration and environmental conditions.

3. How do the time requirements compare between 3D and traditional alignment methods?

3D wheel alignment systems are typically much faster, often reducing alignment times from hours to minutes compared to traditional methods.

4. Which method requires more operator skill and training?

Traditional methods generally require more operator skill and experience, as the accuracy heavily depends on the technician’s expertise. 3D systems, while having a steeper initial learning curve, often provide more consistent results across different operators.

5. What are the cost implications of choosing 3D systems over traditional methods?

3D alignment systems usually require a higher initial investment. However, they can be more cost-effective in the long run due to increased speed, accuracy, and customer satisfaction. Ongoing costs for calibration and software updates should also be considered.

6. Can 3D alignment systems work with all types of vehicles?

While 3D systems are versatile, they may face challenges with certain vehicle designs or in extreme lighting conditions. Traditional methods might be preferred in some specific scenarios.

Describe Your Needs In Detail!

We will carefully evaluate your needs and give professional solutions.