Description GI-610 is an advanced garage equipment used to clean and test injectors of petrol

vehicles and motorcycles. It perfectly simulates engine working conditions to help

workshops and 4S stores save time and money to test and clean injectors.

Features Six Fuel Injectors

To perform simultaneous cleaning on several injectors and to remove the carbon

deposits on the injector completely, there are six measuring glass tubes that are

transparent and have a clear scale on them.

Ultrasonic Cleaning

It sends signals to the injectors through the pulse signal line, using the cleaning

fluid with ultrasonic vibration so as to completely remove the carbon and impurities

inside the injectors.

Easy-operate Panel

The simple and clear buttons on the panel make the operation of the injector cleaning

machine easy. The icons on the panel are easy to understand.

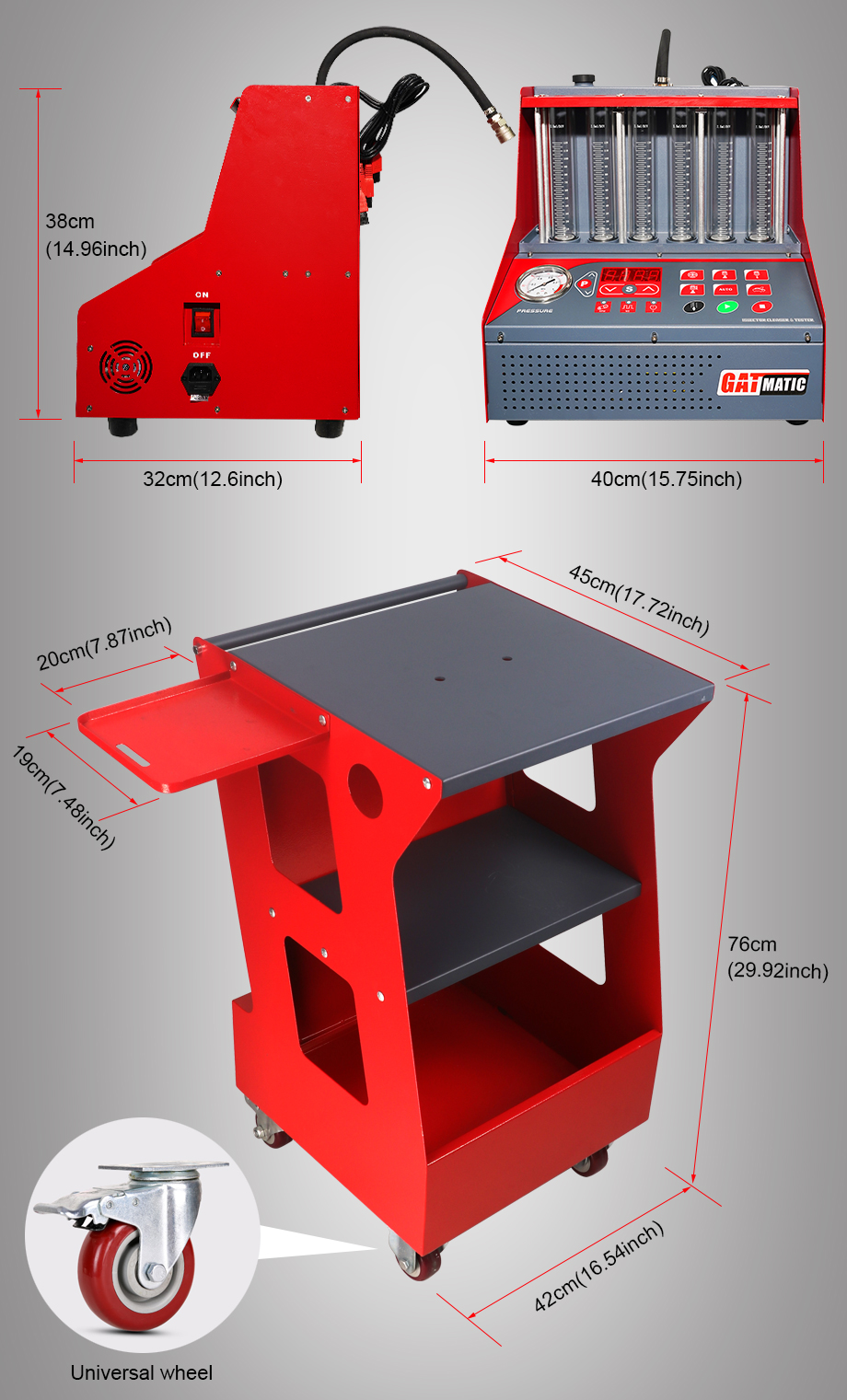

Large Storage Capacity

GI-610 is equipped with a storage cabinet that can store cleaning fluid, maintenance

tools, etc. And it can move easily with its casters to follow you wherever you work.

Multiple Functions

1. Direct Flush

Structure Instruction

Factory of Fuel Injector Cleaner Machine GAT

injector testers & cleaners, A/C recovery machines, 3D wheel aligners, tire changers,

wheel balancers, tool trolleys , and so on.

All GAT products are characterized by advanced technology, top-quality design, and

robust manufacturing. The GI-610 is designed for testing and cleaning injectors of

petrol vehicles and motorcycles.

Specification

Power Supply AC220V-50/60Hz, AC110V-60Hz

Input Power 200W

Ultrasonic Cleaner Power 60W

Pressure 0-7bar

Accuracy of Tube ±2%

RPM Range 0-9999RPM

PW Range 0.1-30ms, step:0.1ms

Timing 1-30min