Screw Tight: How the Right High-strength Socket Wrench Set Can Save Your Project.

In the realm of construction, automotive maintenance, and various do-it-yourself projects, the tools we choose can often be the deciding factor between success and failure. This is particularly true when it comes to fastening and loosening screws, where precision and efficiency are paramount. Among the arsenal of tools, high-strength socket wrench sets stand out as unsung heroes, playing a crucial role in the seamless execution of projects. This essay explores the significance of these specialized tools, delving into their characteristics, benefits, and the impact they can have on project outcomes.

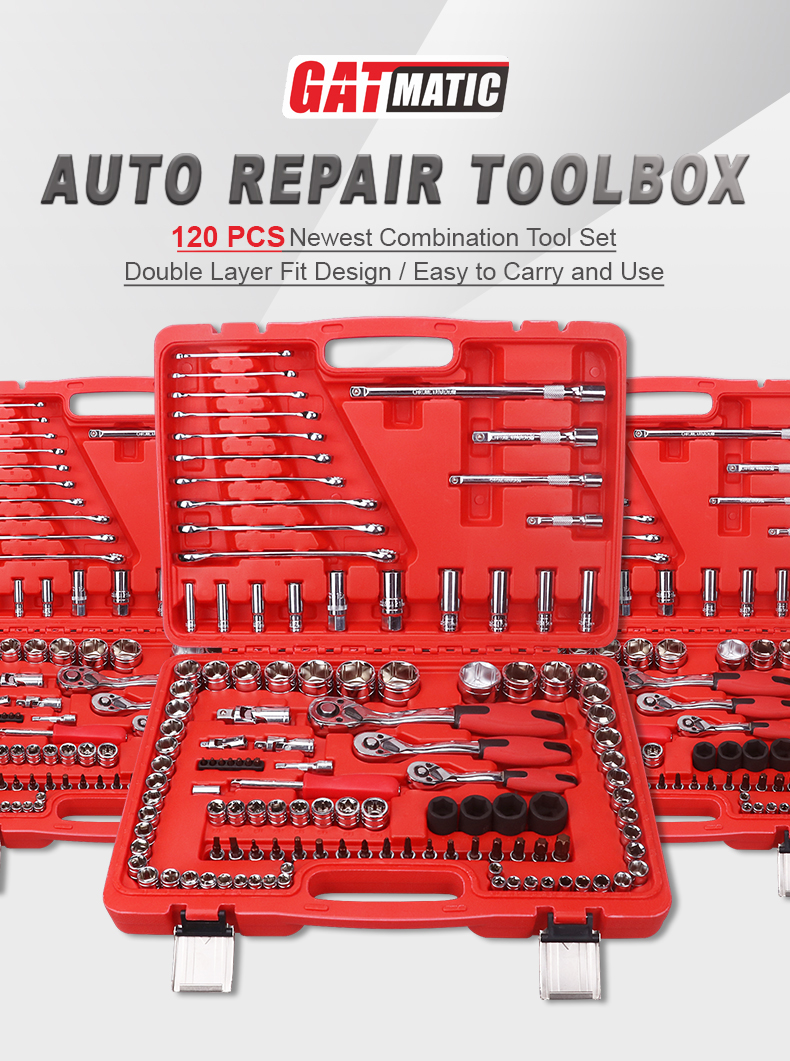

I. Understanding High-strength Socket Wrench Sets

High-strength socket wrench sets, unlike their standard counterparts, are designed to handle more demanding tasks. Characterized by their robust construction and advanced materials, these sets offer increased torque and power, making them indispensable for projects involving heavy-duty fasteners and challenging applications. Their ability to withstand high levels of stress and pressure sets them apart in the realm of construction, automotive repair, and other fields where durability is non-negotiable.

II. Benefits of Using High-strength Socket Wrench Sets

The benefits of utilizing high-strength socket wrench sets are multifaceted. First and foremost, their enhanced torque capabilities empower users to tackle tasks that would be daunting or even impossible with standard sets. This increased power translates into improved efficiency and speed, ultimately saving valuable time on projects.

Furthermore, the durability of high-strength socket wrench sets is a game-changer. In comparison to their standard counterparts, these tools are engineered to withstand the wear and tear of rigorous use. This not only contributes to their longevity but also ensures that they maintain peak performance throughout the lifespan of a project. Versatility is another key advantage, allowing these sets to handle various fasteners with ease, providing a one-stop solution for a diverse range of applications.

III. Case Studies

Real-life examples vividly illustrate the impact of high-strength socket wrench sets on project outcomes. In the construction industry, for instance, professionals have reported a substantial reduction in project timelines when using these specialized tools. Automotive technicians praise the efficiency of high-strength socket wrench sets in dealing with stubborn, rusted bolts, highlighting the tools’ ability to navigate challenging situations seamlessly.

IV. Choosing the Right High-strength Socket Wrench Set

Selecting the appropriate high-strength socket wrench set for a project requires careful consideration. Factors such as torque requirements, compatibility with different fasteners, and the specific needs of the project must be taken into account. Reading user feedback and thoroughly reviewing product specifications can guide individuals in making informed decisions, ensuring that the chosen set aligns with the unique demands of their projects.

V. Maintenance and Care

To maximize the benefits of high-strength socket wrench sets, proper maintenance is essential. Regular cleaning, lubrication, and appropriate storage contribute to the longevity of these tools, preserving their performance over time. Investing time and effort in maintaining these tools is a small price to pay for the long-term efficiency they bring to projects.

Conclusion

In conclusion, the right tools can be the linchpin of project success, and high-strength socket wrench sets emerge as indispensable assets in this regard. Their ability to provide increased torque, durability, and versatility can save time, reduce costs, and ensure the successful completion of projects. As we navigate the challenges of construction, automotive repair, and various DIY endeavors, the high-strength socket wrench set stands as a testament to the transformative power of quality tools in achieving outstanding results.

FAQs

1. What distinguishes high-strength socket wrench sets from standard sets?

High-strength socket wrench sets are designed with robust construction and advanced materials, providing increased torque and power. They are tailored for heavy-duty tasks and challenging applications, setting them apart from standard sets.

2. Why are high-strength socket wrench sets essential for projects?

These specialized sets offer enhanced torque, durability, and versatility, making them crucial for tasks involving tough fasteners and demanding applications. They contribute to project efficiency, saving time and ensuring successful outcomes.

3. In which industries are high-strength socket wrench sets most commonly used?

High-strength socket wrench sets find applications in various industries, including construction, automotive repair, manufacturing, and DIY projects. They are particularly valuable in scenarios where precision, efficiency, and durability are paramount.

4. How do high-strength socket wrench sets save time on projects?

The increased torque and power of high-strength sets allow users to complete tasks more efficiently. They can handle challenging fasteners with ease, reducing the time required for fastening and loosening screws, ultimately expediting project timelines.

5. What benefits do high-strength socket wrench sets offer in terms of durability?

These sets are engineered to withstand high levels of stress and pressure, ensuring durability in demanding work conditions. Their robust construction and quality materials contribute to a longer lifespan, reducing the need for frequent replacements.

Describe Your Needs In Detail!

We will carefully evaluate your needs and give professional solutions.