The Importance of Insulated Tools on Car Repair

Insulated tools may not always be the first thing on the minds of vehicle technicians or mechanics when working on Electric or Hybrid Vehicles (EHVs), but they are crucial for safety reasons. In fact, an insulated tool kit should be a fundamental part of any technician’s or mechanic’s equipment, particularly with the growing number of electric and hybrid vehicles on the road. With these tools readily available, technicians and mechanics can perform their tasks with confidence, professionalism, and safety in mind.

What are insulated tools

Insulated tools are tools that are designed and constructed with insulating materials to provide protection against electrical shock. These tools are commonly used by electricians and other professionals who work with live electrical circuits and equipment.

The handles of insulated tools are typically made of materials such as rubber, plastic, or composite materials that have high dielectric strength, which means they can resist electrical current. The insulation on the handles helps to prevent electric current from traveling through the tool and into the user’s body, reducing the risk of electrical shock.

Insulated tools are generally tested and certified to meet specific safety standards, such as the International Electrotechnical Commission’s (IEC) 60900 standard for insulated hand tools. These standards require that the tools meet certain electrical and mechanical requirements and undergo rigorous testing to ensure their safety and effectiveness.

Examples of insulated tools include pliers, screwdrivers, wrenches, cutters, and other hand tools. They are essential for any worker who may come into contact with live electrical circuits and equipment, as they provide an extra layer of protection against electrical shock.

Why should I use insulated tools

You should use insulated tools if you work with live electrical circuits or equipment, or in any situation where there is a risk of electrical shock. Here are a few reasons:

- Safety: Insulated tools provide an extra layer of protection against electrical shock. The insulation on the handles helps to prevent electric current from traveling through the tool and into your body, reducing the risk of injury or death from electrocution.

- Compliance: If you work in an industry where there are safety regulations or guidelines related to electrical safety, such as the Occupational Safety and Health Administration (OSHA) standards in the United States, using insulated tools may be a requirement.

- Confidence: Insulated tools give you added confidence and peace of mind when working with live electrical circuits and equipment. Knowing that you are using tools designed specifically to protect you from electrical shock can help you focus on your work and perform your tasks more efficiently.

- Longevity: Insulated tools are often more durable than non-insulated tools, as the insulation materials used on the handles can help to protect the tools from damage due to exposure to chemicals, moisture, or other harsh environments.

Overall, using insulated tools is an important step in ensuring your safety and the safety of those around you when working with live electrical circuits and equipment.

Looking for the best-quality insulated tools? Contact GATmatic

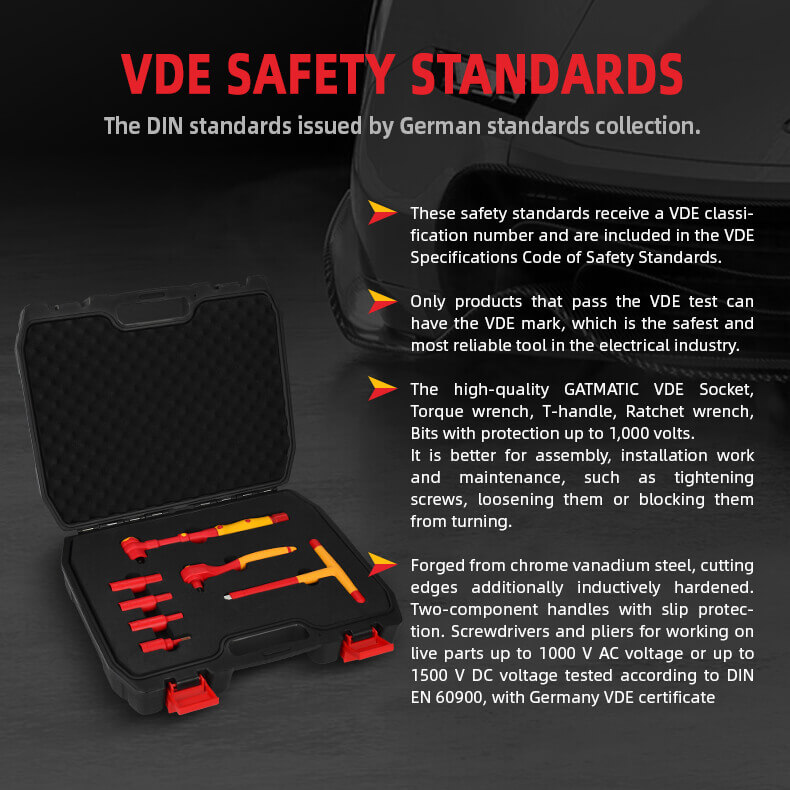

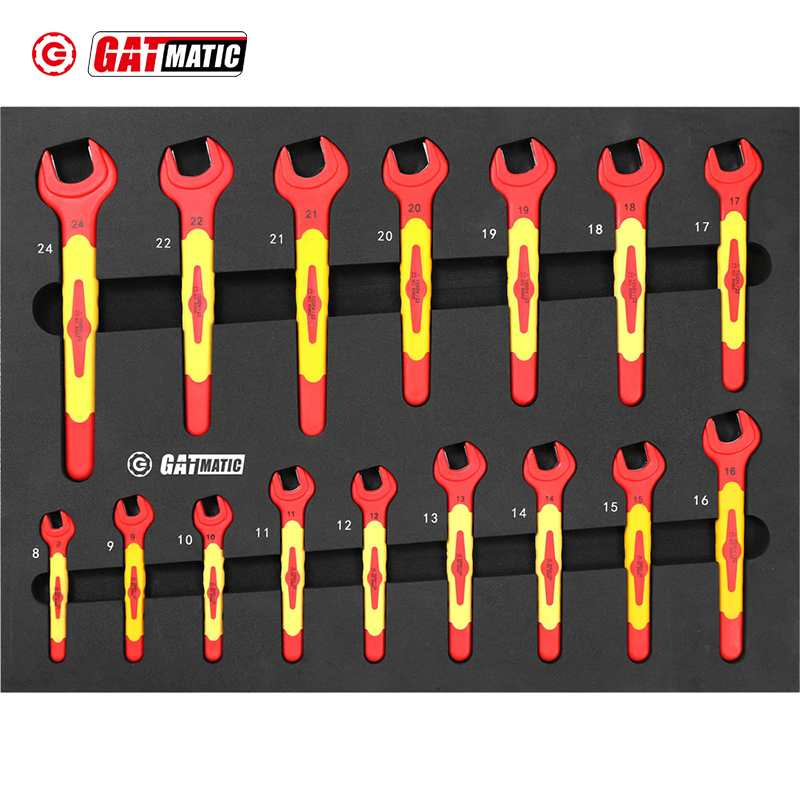

Thanks to the experience gained in the safety and electrical protection sector, GATmatic offers customers reliable, and professional insulated tool kits and tool trolley with insulated tools. All insulated tools from GATmatic have marked VDE (Verband Deutscher Elektrotechniker) certification. Tools for working on live parts are up to 1000V AC voltage or 1500V DC voltage, which is the safest and most reliable tool in the electrical industry. Moreover, our insulated tools are manufactured for International Electrotechnical Commission (IEC) 60900 standards for use in hazardous work environments.

|

|

Most notably, our insulated tools are featured with the EVA foam storage tray which is designed with special pockets custom-fit for each tool, designed to keep your insulated tools organized and all in one pallet.

|

|

|

|

|

|

FAQs

Q1: What types of insulated tools are available?

A1: Insulated tools are available in a wide variety of types, including pliers, screwdrivers, wrenches, cutters, and more. Some manufacturers also offer complete tool sets that include a range of insulated tools.

Q2: How are insulated tools tested and certified?

A2: Insulated tools are typically tested and certified according to specific safety standards, such as the International Electrotechnical Commission’s (IEC) 60900 standard for insulated hand tools. The testing process may involve subjecting the tools to various electrical and mechanical tests to ensure their safety and effectiveness.

Q3: Can I use insulated tools for non-electrical tasks?

A3: Yes, insulated tools can be used for non-electrical tasks as well. However, they may be slightly heavier or bulkier than non-insulated tools due to the added insulation on the handles.

Q4: How do I care for my insulated tools?

A4: To maintain the integrity of the insulation on your tools, it’s important to keep them clean and dry. Avoid using abrasive cleaners or solvents that may damage the insulation, and store your tools in a dry location when not in use.

Q5: How often should I replace my insulated tools?

A5: The lifespan of insulated tools can vary depending on factors such as usage, storage conditions, and exposure to harsh environments. It’s generally a good idea to inspect your insulated tools regularly for signs of damage or wear and to replace them if the insulation becomes cracked, damaged, or worn.

Describe Your Needs In Detail!

We will carefully evaluate your needs and give professional solutions.