Recent Blog

-

CCD Alignment Systems VS. 3D Alignment Systems

2025-04-08 -

What are the main differences between 2D and 3D wheel alignment systems

2025-03-26 -

Is Touchless Wheel Alignment Right for You? Factors to Consider

2025-03-19 -

The Future of Automotive Service: Exploring Touchless Wheel Alignment Technology

2025-03-13

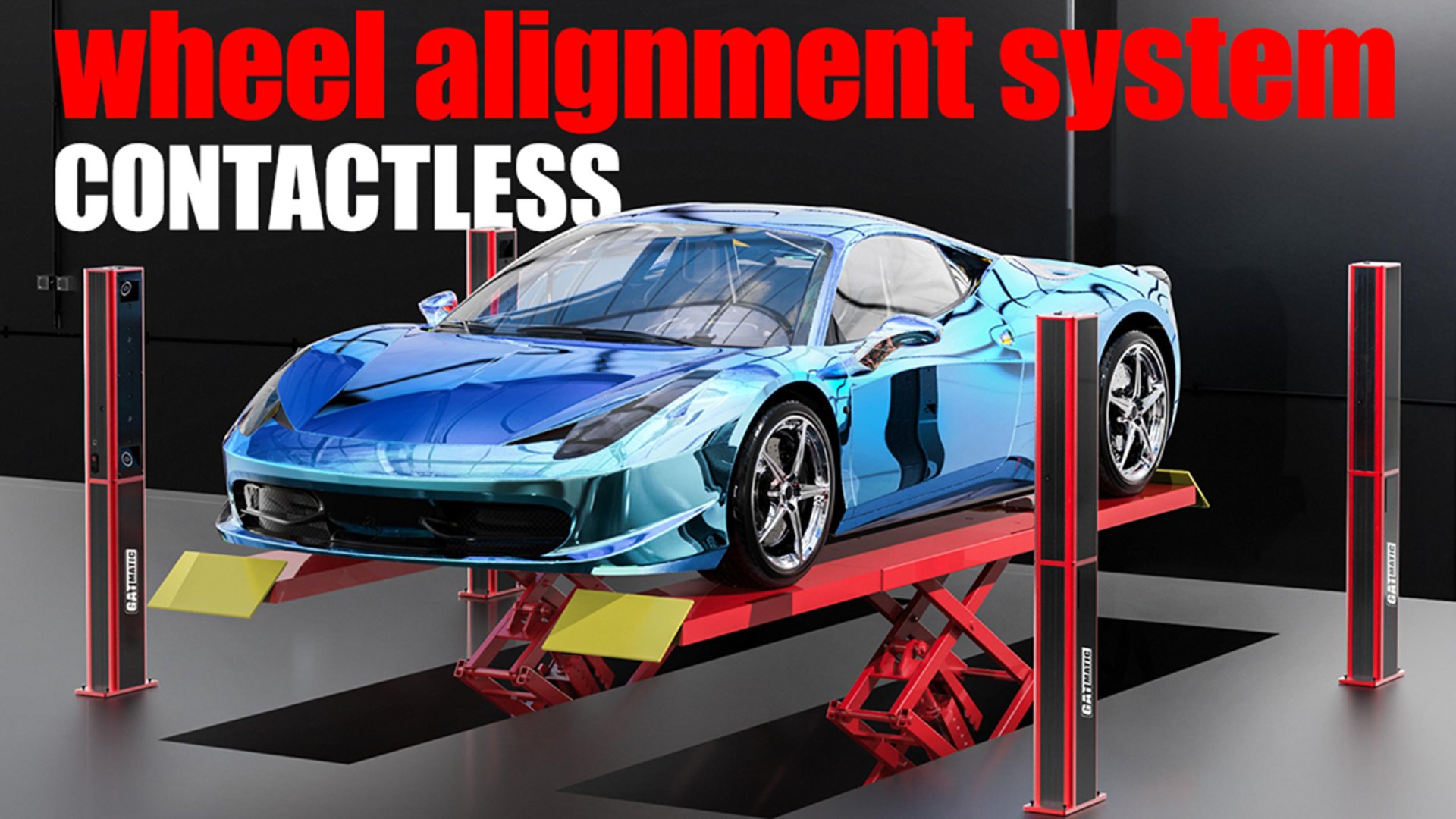

What are the main benefits of using a touchless wheel alignment system

I. The Main Benefits of Using a Touchless Wheel Alignment System

In the ever-evolving automotive service industry, ensuring optimal vehicle performance is paramount. One of the most critical aspects of vehicle maintenance is wheel alignment, which directly affects tire wear, fuel efficiency, and overall driving safety. Traditionally, wheel alignment processes involved cumbersome physical equipment and manual measurements. However, the advent of touchless wheel alignment systems has revolutionized this service. This essay explores the main benefits of using a touchless wheel alignment system, highlighting its precision, time efficiency, user-friendly interface, reduced wear and tear, enhanced customer experience, cost reduction, and increased convenience.

II. Precision and Accuracy

One of the standout features of touchless wheel alignment systems is their exceptional precision and accuracy. Utilizing advanced laser technology and sophisticated algorithms, these systems minimize measurement errors that can occur with traditional methods. By employing optical technology to measure alignment angles—such as toe, camber, and thrust—touchless systems deliver highly accurate results. For instance, systems like the CEMB ARGOS can measure alignment in mere seconds while ensuring that adjustments are precise. This level of accuracy not only enhances vehicle performance but also instills confidence in both technicians and customers regarding the quality of service provided.

III. Time Efficiency

In a fast-paced automotive service environment, time is a crucial factor. Touchless wheel alignment systems significantly reduce the time required to set up and complete alignment tasks. Traditional methods often involve lengthy setup times and manual adjustments; however, touchless technology streamlines this process. With the ability to measure alignment in approximately five seconds, workshops can increase their throughput and maximize potential profits. Additionally, labor time is reduced as there is no need to install wheel clamp targets or other physical attachments—allowing technicians to focus on providing quality service rather than dealing with cumbersome equipment.

IV. User-Friendly Interface

Touchless wheel alignment systems are designed with user-friendliness in mind. Their intuitive software guides technicians through the alignment process step by step, making it accessible to mechanics of all skill levels. This design minimizes the learning curve and reduces human error during operation. The simplified setup process—free from physical attachments—allows for faster operation and less hassle for technicians. Furthermore, sophisticated software captures alignment data and provides analysis and diagnostic capabilities that empower technicians to make informed decisions about necessary adjustments.

V. Reduced Wear and Tear

Another significant advantage of touchless wheel alignment systems is their ability to reduce wear and tear on both vehicles and equipment. The non-contact nature of these systems eliminates the risk of damage to wheels and rims during the measurement process. This not only protects customers’ vehicles but also saves workshops from potential liability claims arising from accidental damage. Moreover, since there are no physical clamps or sensors making contact with tires or wheels, there is minimal wear on these components—extending their lifespan and enhancing overall vehicle performance.

VI. Enhanced Customer Experience

Investing in cutting-edge technology like touchless wheel alignment systems demonstrates a commitment to providing high-quality service. This investment attracts customers who seek advanced solutions for their vehicles. Furthermore, transparency is increased as customers can be involved in the process; they gain a better understanding of the value of the work being performed on their vehicles. By showcasing state-of-the-art technology in action, workshops can enhance customer trust and satisfaction.

VII. Cost Reduction

Touchless wheel alignment systems can also lead to significant cost reductions for automotive service providers. The need for additional tools or devices is minimized, which subsequently lowers repair and maintenance costs associated with traditional equipment. Additionally, because touchless systems eliminate the need for leveled lifts or racks—further reducing overhead costs—workshops can operate more efficiently while maintaining high standards of service.

VIII. Increased Efficiency and Convenience

Finally, touchless wheel alignment systems enhance overall efficiency and convenience within the workshop environment. The contactless operation improves safety by reducing the need for technicians to exit vehicles during measurements. This not only streamlines workflow but also allows technicians to focus on performing quality alignments without unnecessary interruptions. Moreover, these systems automatically recalibrate when a vehicle leaves the site, ensuring that adjustments remain accurate even after service completion.

Conclusion

In conclusion, touchless wheel alignment systems represent a significant advancement in automotive service technology. Their benefits—including precision and accuracy, time efficiency, user-friendly interfaces, reduced wear and tear on vehicles, enhanced customer experiences, cost reductions, and increased convenience—make them an invaluable asset for any workshop aiming to provide high-quality vehicle maintenance services. As the automotive industry continues to evolve, embracing innovative solutions like touchless wheel alignment will undoubtedly lead to improved performance outcomes for both technicians and customers alike.

FAQs

1: What is touchless wheel alignment?

Touchless wheel alignment is a method of aligning a vehicle’s wheels without physically touching the tires or using traditional clamps and targets. It uses advanced technologies like lasers, cameras, and other optical sensors to measure and analyze alignment angles remotely.

2: How does touchless wheel alignment work?

Touchless systems use advanced laser image algorithms and 3D measurement technology. The vehicle is parked on a lift equipped with the system, and the system’s scanners measure the toe, camber, and thrust angles, often in as little as 5 seconds.

3: Is touchless wheel alignment more accurate than traditional methods?

Yes, the advanced optical technology used in touchless systems provides high precision and accuracy when measuring alignment angles, allowing for more accurate adjustments.

4: How much time can be saved using a touchless wheel alignment system?

Touchless systems can measure alignment in approximately 5 seconds. The entire alignment process takes mere seconds.

5: Do touchless wheel alignment systems require any special equipment or tools?

No, touchless systems eliminate the need for traditional clamps, sensors, or targets. They also reduce the need for leveled lifts, racks, or detectors.

Describe Your Needs In Detail!

We will carefully evaluate your needs and give professional solutions.