Recent Blog

-

CCD Alignment Systems VS. 3D Alignment Systems

2025-04-08 -

What are the main differences between 2D and 3D wheel alignment systems

2025-03-26 -

Is Touchless Wheel Alignment Right for You? Factors to Consider

2025-03-19 -

The Future of Automotive Service: Exploring Touchless Wheel Alignment Technology

2025-03-13

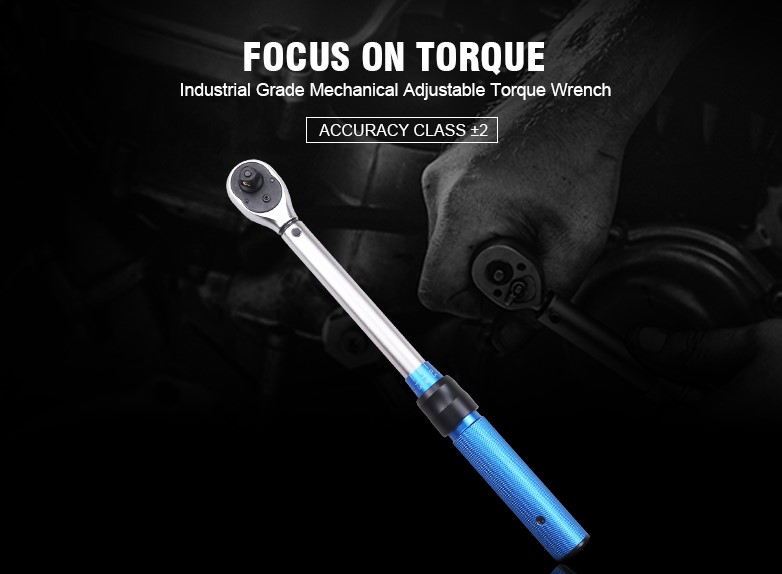

WHAT IS A TORQUE WRENCH AND WHY YOUR TOOLBOX NEEDS ONE

In the world of mechanics and engineering, the precise application of torque plays a vital role in ensuring the integrity and functionality of various systems. From the automotive to aerospace industries, achieving accurate torque is crucial. That’s where a torque wrench comes into play. This essay explores the concept of a torque wrench, its significance in achieving proper torque, and why it deserves a place in your toolbox.

What is a Torque Wrench & Its Application

A torque wrench is a specialized tool designed to apply a specific amount of torque to fasteners such as bolts and nuts. It serves the fundamental purpose of tightening or loosening these fasteners with a controlled force. Unlike regular wrenches or ratchets, torque wrenches are engineered to provide precise torque measurement and application, ensuring that fasteners are neither under-tightened nor over-tightened.

Torque wrenches find widespread use across various industries. In the automotive and vehicle maintenance sector, they are essential for tasks ranging from engine assembly to wheel installation. In the aerospace and aviation industry, where precision and safety are paramount, torque wrenches are indispensable for aircraft assembly and maintenance. Manufacturing and assembly lines rely on torque wrenches to ensure proper torque specifications are met during production. Even in construction and engineering projects, torque wrenches play a critical role in ensuring structural integrity and equipment reliability.

Types of Torque Wrenches

There are several types available in the market. Each type has its own unique features and benefits, catering to different applications and user preferences. Here are some of the commonly used types of torque wrenches:

- Beam Torque Wrench:

- This is one of the simplest and most straightforward types of torque wrenches.

- It features a long handle with a lever arm and a marked scale.

- As torque is applied, the lever arm deflects, and the pointer on the scale indicates the torque value.

- Beam torque wrenches are known for their durability and reliability, requiring minimal maintenance.

- Click Torque Wrench:

- Click torque wrenches are widely used due to their ease of use and accuracy.

- They feature a ratcheting mechanism and a calibrated spring-loaded mechanism.

- The user sets the desired torque value by adjusting the wrench.

- When the specified torque is reached, the wrench produces an audible click sound, signaling the user to stop applying force.

- Click torque wrenches are commonly used in automotive and general mechanical applications.

- Dial Torque Wrench:

- Dial torque wrenches utilize a dial gauge to display the torque value being applied.

- The user sets the desired torque value by rotating the handle.

- As torque is applied, the dial gauge indicates the precise torque measurement.

- Dial torque wrenches are known for their ease of readability and are often used in situations where precise torque control is required.

- Electronic Torque Wrench:

- Electronic torque wrenches are advanced tools that utilize electronic components for precise torque measurement.

- They feature a digital display that shows the real-time torque being applied.

- Electronic torque wrenches often provide additional features like programmable torque settings, memory storage, and data logging capabilities.

- These wrenches are commonly used in industries where high accuracy and advanced functionality are required, such as aerospace and manufacturing.

Importance of Using a Torque Wrench

The use of a torque wrench holds significant importance in various industries and applications. Here are several key reasons why using a torque wrench is essential:

- Prevents Overtightening: Over-tightening fasteners can lead to serious consequences. It can damage the fastener itself, surrounding components, or threads. Overtightened fasteners are prone to shearing, stripping, or distortion, compromising the structural integrity of the assembly. A torque wrench ensures that fasteners are tightened to the specified torque, minimizing the risk of overtightening.

- Ensures Proper Clamping Force: Many applications require a specific clamping force to ensure safety, reliability, and optimal performance. Insufficient clamping force due to under-tightening can result in loose connections, leading to vibrations, leaks, or component failure. A torque wrench allows precise control over the applied force, ensuring the correct clamping force is achieved.

- Meets Manufacturer Specifications: Manufacturers provide specific torque requirements for fasteners to ensure proper assembly, function, and longevity of their products. By using a torque wrench, you adhere to these specifications and maintain the integrity of the equipment or system being worked on. It helps ensure that the assembly meets the manufacturer’s recommended standards and guarantees consistent quality.

- Enhances Safety: In many industries, safety is of utmost importance. Using a torque wrench helps prevent accidents and injuries caused by improperly tightened fasteners. Critical applications such as automotive wheel nuts, aircraft components, or structural connections require accurate torque to maintain safety standards. A torque wrench ensures that these safety-critical fasteners are tightened correctly, reducing the risk of failures and potential hazards.

- Avoids Gasket or Seal Failures: In applications involving gaskets or seals, proper torque is crucial to establish a reliable and leak-free seal. Inadequate torque can result in insufficient compression of gaskets or seals, leading to leaks, fluid loss, or reduced performance. By using a torque wrench, the appropriate torque can be applied, ensuring effective sealing and preventing potential failures.

- Consistency and Quality Assurance: Torque wrenches provide consistent and repeatable torque application. This consistency is crucial in assembly line production, where uniform torque application is necessary to maintain product quality and performance. Torque wrenches enable standardized torque values across multiple fasteners, ensuring consistency and enhancing overall quality assurance.

Factors to Consider When Choosing a Torque Wrench

When selecting a torque wrench, several factors should be taken into consideration to ensure the tool meets your specific requirements. Here are some key factors to consider when choosing a torque wrench:

- Required Torque Range and Accuracy: Determine the torque range you need for your applications. Consider both the minimum and maximum torque values required. Additionally, assess the level of accuracy required for your work. Some applications may require higher precision, while others may have more lenient tolerances.

- Type of Fasteners and Specifications: Understand the types of fasteners you will be working with, such as bolts, nuts, or screws. Take note of their size, thread pitch, and the recommended torque specifications provided by the manufacturer. Ensure that the torque wrench you choose is compatible with the fasteners you commonly encounter.

- Ergonomics and Ease of Use: Consider the ergonomics of the torque wrench, including its handle design, weight, and grip comfort. A torque wrench that feels comfortable and intuitive to use will contribute to accurate and efficient torque application. Look for features such as non-slip handles or ergonomic designs that reduce user fatigue during prolonged use.

- Budget and Cost: Set a budget range for your torque wrench purchase. Keep in mind that more advanced or specialized torque wrenches may come at a higher cost. Strike a balance between your budget and the quality and features you require. Remember that investing in a reliable and durable torque wrench can save you money in the long run by preventing damage and ensuring accuracy.

- Calibration and Maintenance: Consider the ease of calibration and maintenance of the torque wrench. Regular calibration is essential to maintain accuracy over time. Some torque wrenches may require specialized calibration equipment or professional services, while others may offer user-friendly calibration mechanisms. Also, assess the maintenance requirements and whether the manufacturer provides support or spare parts when needed.

- Additional Features and Accessories: Some torque wrenches come with additional features or accessories that can enhance usability or versatility. Examples include quick-release mechanisms, reversible ratchets, or interchangeable heads. Assess whether these features are beneficial for your specific applications and if they align with your preferences.

By considering these factors, you can select a torque wrench that suits your needs, provides accurate torque application, and ensures efficiency and reliability in your work. Remember to balance the specific requirements of your applications with the available options and your budget to make an informed decision.

Torque Wrenches from GATmatic

GATmatic is a renowned brand known for its high-quality torque wrenches, offering precision, reliability, and advanced features. With a strong reputation in the industry, GATmatic torque wrenches have become a preferred choice for professionals and enthusiasts alike.

Advantages of GATmatic Torque Wrenches

- Quality and Expertise: GATmatic is synonymous with exceptional quality and craftsmanship. The brand prides itself on its commitment to delivering torque wrenches that meet stringent industry standards. With years of expertise and a dedication to precision engineering, GATmatic has gained a reputation for manufacturing tools that professionals trust.

- Innovation and Technology: GATmatic is at the forefront of torque wrench technology, consistently pushing the boundaries of innovation. The brand invests in research and development to incorporate cutting-edge features into its products. GATmatic torque wrenches often integrate advanced mechanisms, digital displays, and smart functionalities, ensuring accurate torque application and user-friendly experiences.

- Durability and Longevity: GATmatic torque wrenches are built to withstand the demands of rigorous applications. The brand utilizes robust materials and employs rigorous quality control processes to ensure the longevity and reliability of its tools. Professionals who rely on their torque wrenches in challenging environments can trust GATmatic to provide tools that stand the test of time.

Conclusion

A torque wrench is a valuable tool for any toolbox or workshop. Its ability to apply precise torque helps prevent damage to fasteners and components, ensures safety and reliability, and meets industry standards. The versatility of torque wrenches makes them indispensable in the automotive, aerospace, manufacturing, and construction sectors, among others. By considering the necessary factors and properly maintaining and calibrating the tool, one can harness its full potential. So, whether you’re a professional mechanic or a DIY enthusiast, including a torque wrench in your toolbox is a wise investment that will pay off in precision, efficiency, and peace of mind.

Describe Your Needs In Detail!

We will carefully evaluate your needs and give professional solutions.