Why Is It Important to Use Hand Tools According to Their Function?

Hand tools have been essential for human civilization for thousands of years, helping us build, repair, and maintain everything from simple household items to complex machinery. However, one of the most critical aspects of using hand tools is understanding the importance of using each tool according to its specific function. This practice is not just about efficiency, but also about safety, tool longevity, and the quality of the work being performed. In this article, we will explore why it is crucial to use hand tools for their intended purposes and the potential consequences of misusing them.

I. Safety Concerns

Safety is the most compelling reason to use hand tools as intended. Each tool is designed with a specific purpose in mind, taking into account factors such as the type of material it will interact with, the amount of force it can safely withstand, and how it should be handled. When tools are used improperly, the risk of injury increases significantly.

- Tool Design and Safety: Tools are engineered to handle specific tasks safely. For instance, a screwdriver is designed to drive screws and is built to apply force in a way that minimizes the risk of slipping. Using a screwdriver as a pry bar, however, could cause it to snap or slip, potentially leading to hand injuries.

- Personal Injury Risks: Misusing tools can lead to personal injuries. For example, using a wrench as a hammer might seem convenient, but the lack of control and the difference in design can result in broken bones, lacerations, or other serious injuries. By using each tool for its intended purpose, you significantly reduce these risks.

II. Tool Longevity

Using hand tools according to their function also extends their lifespan. When tools are misused, they are subjected to forces and stresses they were not designed to handle, leading to premature wear and damage.

- Preventing Wear and Tear: Tools like pliers, wrenches, and hammers are crafted from specific materials chosen for their durability under certain conditions. When used improperly, these materials can degrade faster, leading to bending, breaking, or dulling.

- Cost-Effective Tool Maintenance: Proper use of tools not only extends their lifespan but also reduces the need for frequent replacements or repairs. This is especially important for professional tradespeople who rely on their tools daily. By preserving your tools through correct usage, you can avoid the unnecessary expense of constantly buying new ones.

III. Efficiency and Work Quality

Using the right tool for the right job not only ensures safety and longevity but also improves the efficiency and quality of your work.

- Precision in Tasks: Each hand tool is designed to perform specific tasks with precision. For example, using a chisel to carve wood allows for detailed, controlled work that cannot be replicated with a tool not designed for that purpose. This precision leads to a higher quality of work, whether you’re building furniture or assembling electronics.

- Time Management: Using the correct tool for a job can save time. Trying to force a tool to perform a task it wasn’t designed for often leads to mistakes, frustration, and additional time spent correcting those errors. On the other hand, using the appropriate tool helps you complete tasks more efficiently and with better results.

IV. Professionalism and Reputation

For professionals in trades such as carpentry, plumbing, or electrical work, the correct use of tools is a matter of professionalism and reputation. Clients expect high-quality work, and part of delivering that quality is using the right tools in the right way.

- Building Trust with Clients: When clients see that you use tools properly and with care, they are more likely to trust your expertise and craftsmanship. This trust can lead to repeat business, referrals, and a stronger professional reputation.

- Avoiding Costly Mistakes: Misusing tools can result in mistakes that are not only costly to fix but can also damage your reputation. For example, using the wrong type of wrench on a delicate pipe can cause irreparable damage, leading to costly repairs and potentially losing a client.

V. Legal and Insurance Implications

In some industries, the misuse of tools can have legal and insurance implications. Many workplaces have strict safety guidelines that must be followed to comply with local laws and regulations.

- Compliance with Safety Regulations: Using tools correctly ensures compliance with safety regulations, which is crucial in avoiding fines, legal issues, and potential workplace shutdowns. Companies and workers can face severe penalties if they are found to be using tools improperly, especially if it results in injury or damage.

- Insurance Coverage: In the event of an accident, insurance claims may be denied if it is found that the tools were not used according to their intended function. This can leave individuals or businesses facing significant financial burdens that could have been avoided by simply using tools correctly.

VI.Commonly Misused Tools and Their Consequences

To better understand the importance of using hand tools according to their function, let’s take a look at some commonly misused tools and the potential consequences:

- Screwdrivers: Often used as pry bars or chisels, screwdrivers can bend, break, or cause injury when misused. The tip can easily be damaged, rendering the tool less effective for its intended purpose.

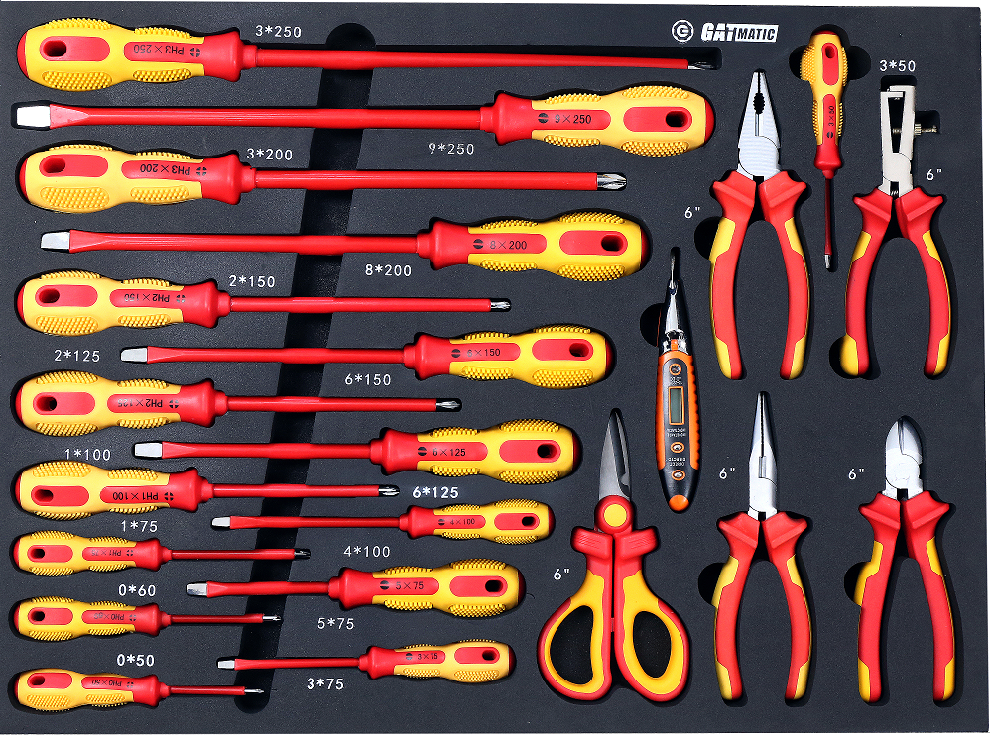

- Pliers: Using pliers as a wrench can lead to rounded-off fasteners, damaged plier jaws, and injury from slippage. Pliers are designed for gripping, not turning bolts, and using them as such can damage both the tool and the workpiece.

- Hammers: Using a hammer for tasks other than striking, such as prying or breaking materials, can result in broken handles or chipped heads, which can cause injury to the user.

- Wrenches: Misusing a wrench, such as using it as a hammer or using the wrong size, can strip bolts, damage the wrench, and lead to slips that cause injury.

Conclusion

Using hand tools according to their intended function is crucial for maintaining safety, extending the life of your tools, improving work quality, and ensuring professionalism. Whether you’re a DIY enthusiast or a professional tradesperson, the importance of proper tool usage cannot be overstated. By understanding the purpose of each tool and using it correctly, you can avoid unnecessary risks, save time and money, and produce high-quality work that stands the test of time.

Frequently Asked Questions (FAQs)

Q: What should I do if I don’t have the right tool for a job?

A: It is always recommended to use the correct tool for the job. If you don’t have the right tool, consider borrowing, renting, or purchasing it. Improvising with the wrong tool can lead to mistakes, damage, and injury.

Q: Can using the wrong tool really void warranties?

A: Yes, using tools improperly can void warranties on both the tool and the work being performed. Many manufacturers include clauses in their warranties that exclude coverage if the tool has been misused.

Q: What are some signs that a tool is being used improperly?

A: Signs of improper tool use include visible damage to the tool, such as bent or broken parts, difficulty in performing the task, or excessive wear on the tool or the material being worked on.

Q: How can I learn to use tools correctly?

A: To learn proper tool usage, consider taking a workshop, watching instructional videos, or consulting the tool’s manual. Many manufacturers also provide guidelines on their websites for using their tools safely and effectively.

Q: Are there specific tools that are more prone to misuse?

A: Yes, tools like screwdrivers, pliers, and hammers are often misused because they are versatile and commonly found in toolboxes. It’s important to resist the temptation to use these tools for tasks they weren’t designed to handle.

Describe Your Needs In Detail!

We will carefully evaluate your needs and give professional solutions.